As a LiFePO4 Battery Manufacturer, share with you. There are a lot of LiFePO4

battery, but there are some disadvantages.

LiFePO4 Battery

LiFePO4 Battery also has its shortcomings: for example, poor low temperature performance, low tap density of the positive electrode material, and lithium iron phosphate battery of equal capacity is larger than lithium ion batteries such as lithium cobaltate, so it has no advantage in micro batteries. When used in power batteries, lithium iron phosphate batteries, like other batteries, need to face battery consistency issues.

Threat of elemental iron

During the sintering process during the preparation of lithium iron phosphate, there is a possibility that iron oxide is reduced to elemental iron under a high-temperature reducing atmosphere. Elemental iron can cause micro short circuits in batteries and is the most taboo substance in batteries. This is also the main reason why Japan has not used this material as a positive electrode material for power lithium-ion batteries.

Performance defect

There are some performance defects of lithium iron phosphate, such as the low tap density and compaction density, which leads to a lower energy density of lithium ion batteries. The low temperature performance is poor, even if it is nano-sized and carbon coated, it does not solve this problem. The test results of lithium iron phosphate lithium-ion batteries indicate that lithium iron phosphate batteries cannot make electric vehicles run at low temperatures (below 0 ° C). Although some manufacturers claim that the lithium iron phosphate battery has a good capacity retention rate at low temperatures, it is under the condition that the discharge current is small and the discharge cut-off voltage is very low. In this situation, the device simply cannot start working.

High manufacturing cost

The material preparation cost is higher than the battery manufacturing cost, the battery yield is low, and the consistency is poor. Although nano-lithium iron phosphate and carbon coating improve the electrochemical performance of the material, it also brings other problems, such as reduction of energy density, increase of synthesis cost, poor electrode processing performance, and harsh environmental requirements. Although the chemical elements Li, Fe, and P in lithium iron phosphate are abundant and the cost is low, the cost of the prepared lithium iron phosphate product is not low. Even if the previous R & D costs are removed, the process cost of the material plus the The cost of preparing the battery will make the final unit of energy storage cost higher.

Poor consistency

Poor product consistency. Whether it is made from materials or manufactured. It is difficult to ensure the consistency of the product, and the voltage platform of lithium iron phosphate is narrow, which makes the observability of the battery more difficult.

Our company also has Dewalt Battery 3.6V on sale, welcome to consult.

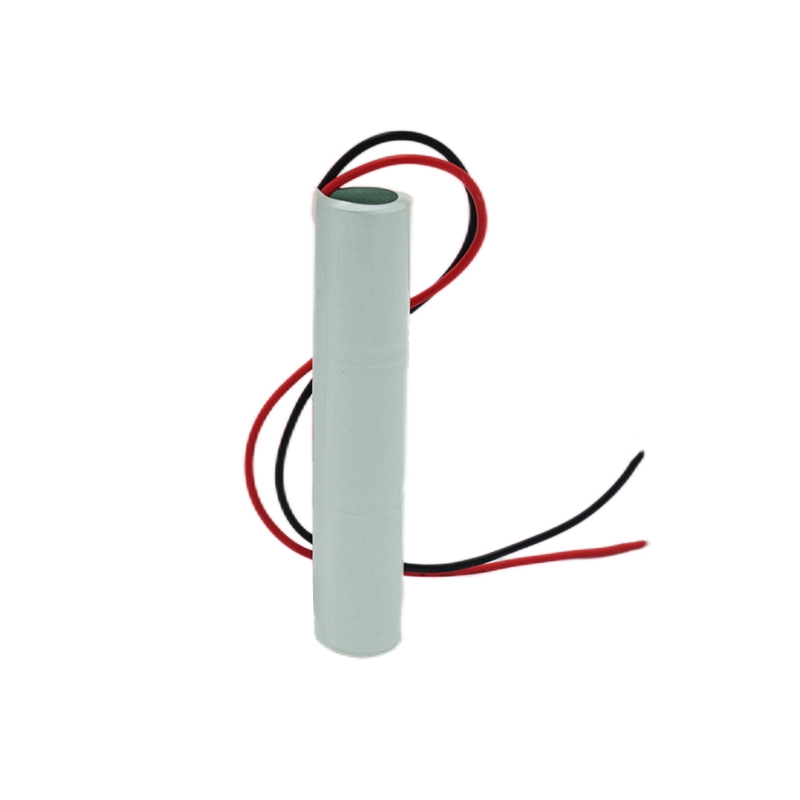

Ni-MH Battery C4700mAh 3.6V

Ni-MH Battery C4700mAh 3.6V Nickel Cadmium Nicd Battery Pack SC1800mAh 3.6V

Nickel Cadmium Nicd Battery Pack SC1800mAh 3.6V Ni-Cd Battery Pack D4000mAh 3.6V

Ni-Cd Battery Pack D4000mAh 3.6V Ni-Cd Battery Pack C2500mAh 3.6V

Ni-Cd Battery Pack C2500mAh 3.6V NICAD Battery Pack AA900mAh 3.6V

NICAD Battery Pack AA900mAh 3.6V LiFePO4 IFR18650 1600mAh 3.2V

LiFePO4 IFR18650 1600mAh 3.2V LiFePO4 IFR18650 1600mAh 6.4V

LiFePO4 IFR18650 1600mAh 6.4V Ni-MH Battery C4000mAh 3.6V

Ni-MH Battery C4000mAh 3.6V E-bike Battery 48V 10Ah JL-1

E-bike Battery 48V 10Ah JL-1 E-bike battery 48V 10Ah Qing Tian

E-bike battery 48V 10Ah Qing Tian