Like all technologies, lithium-ion batteries have been developed for decades

and combined with new chemical methods for different applications and improved

performance. As a Power Tool Batteries Supplier, share with you.

Lithium-Ion Battery is essential to today's technology and can be found in almost all portable devices as well as electric vehicles. Smartphones, laptops, tablets, cordless power tools, and grid energy storage are just a few examples of high-quality batteries that have been the mainstay of electronics since their commercialization in 1991. the popularity of batteries is partly due to their ability to pack large amounts of energy into relatively small spaces at low weight.

Lithium-Ion Battery

Like most batteries, lithium-ion batteries provide the same components inside the battery to generate power-positive electrodes, negative electrodes, and electrolytes through chemical reactions. for example, in the most widely used lithium-ion technology (for mobile devices), the positive electrode is made of lithium iron phosphate (LiFePO4), the negative electrode is usually made of carbon (graphite), and the electrolyte is usually composed of the following materials: lithium salt in organic solvents.

Like all technologies, lithium-ion batteries have been developed for decades and combined with new chemical methods for different applications and improved performance. in this review, we will introduce some of the latest chemistry and compositions developed for lithium-ion batteries and their applications.

Lithium cobalt

LiCoO22 batteries, made of lithium carbonate and cobalt, have a very stable capacity and high specific energy, making it a popular choice to use with mobile devices such as smartphones, laptops and digital cameras.

Inside, they consist of cobalt oxide cathode and carbon graphite anode. during the discharge, lithium ions travel from the anode to the cathode, which is reversed during the charging cycle. these batteries do have some drawbacks, including relatively short life cycles, lower thermal stability and less load capacity, which means they need to be charged frequently.

Lithium manganese

MnO2 batteries actually have two versions: one with a spinel structure (LiMn2O4) with a cathode 3 D frame that can insert and expel lithium ions during the battery's charging and discharging cycles. another is the layered rock salt structure (Li2MnO3) with alternating lithium and lithium/manganese ion layers on the cathode.

Both provide fast charging and high current discharge, and have higher thermal stability than cobalt oxide batteries, and thus improve safety, making it an ideal choice for medical devices, electric vehicles and power tools.

Lithium iron phosphate

LiFePO4 Cell Mold uses iron phosphate as a cathode, and a graphite electrode is combined with a metal collector grid to serve as an anode. compared with other li-ion batteries, these cells have higher tolerance under charged conditions and are less susceptible to pressure when subjected to high voltage for a long time.

as a result, these types benefit from low resistance properties, thereby improving their safety and heat resistance, making them ideal for electric motorcycles and vehicles. the only drawback is their low-voltage capacity and provides less energy than other types of lithium-ion batteries.

Lithium nickel manganese cobalt oxide

LiNiMnCoO2 batteries are made using several different elements common in other lithium-ion batteries and use combinations of nickel, manganese and cobalt as cathodes. although the exact material ratio varies from manufacturer to manufacturer, common combinations are typically 60% nickel ,20% manganese and 20% cobalt.

Like other types of batteries, these batteries can have high specific energy or high specific power (not both), but the inclusion of nickel can provide high specific energy for the battery, although it also reduces stability.

On the other hand, manganese has low internal resistance, but has the disadvantage of low specific energy. However, combining the two enhances each other's advantage and makes it suitable for EV powertrain and cordless power tools.

Lithium nickel cobalt aluminum oxide

Lithium nickel-cobalt-aluminum oxide (LiNiCoAlO2) batteries are not common in the consumer industry, but they have broad prospects for electric vehicle manufacturers (and other professional applications) because they offer high energy options, reasonable good specific power and good service life.

These types of safety are not so listed for other safety, therefore, special safety monitoring measures are needed for electric vehicles. their manufacturing costs are also higher, thus limiting the feasibility of their use in other applications.

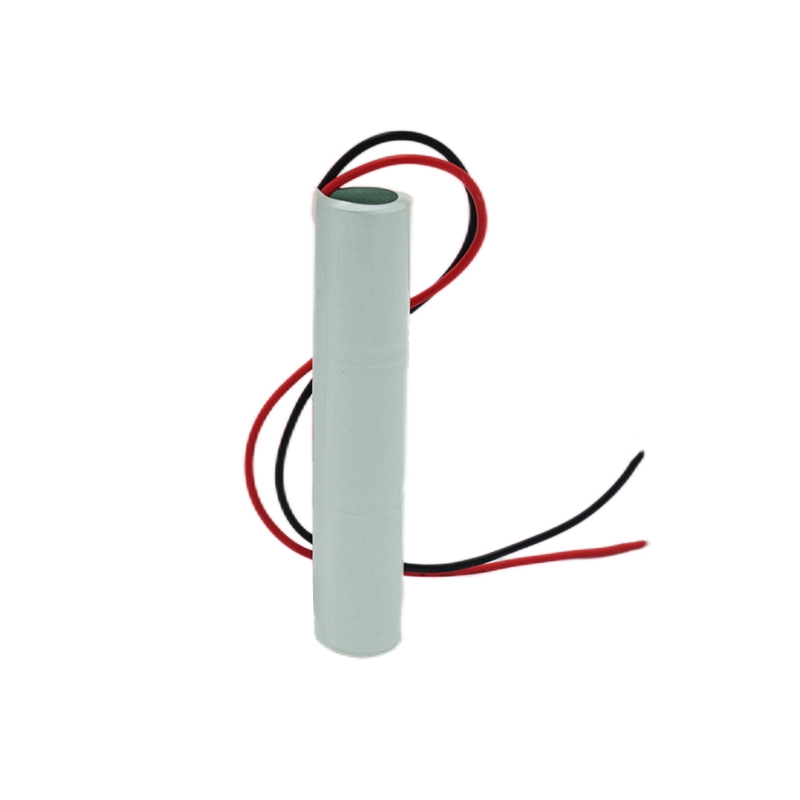

Ni-MH Battery C4700mAh 3.6V

Ni-MH Battery C4700mAh 3.6V Nickel Cadmium Nicd Battery Pack SC1800mAh 3.6V

Nickel Cadmium Nicd Battery Pack SC1800mAh 3.6V Ni-Cd Battery Pack D4000mAh 3.6V

Ni-Cd Battery Pack D4000mAh 3.6V Ni-Cd Battery Pack C2500mAh 3.6V

Ni-Cd Battery Pack C2500mAh 3.6V NICAD Battery Pack AA900mAh 3.6V

NICAD Battery Pack AA900mAh 3.6V LiFePO4 IFR18650 1600mAh 3.2V

LiFePO4 IFR18650 1600mAh 3.2V LiFePO4 IFR18650 1600mAh 6.4V

LiFePO4 IFR18650 1600mAh 6.4V Ni-MH Battery C4000mAh 3.6V

Ni-MH Battery C4000mAh 3.6V E-bike Battery 48V 10Ah JL-1

E-bike Battery 48V 10Ah JL-1 E-bike battery 48V 10Ah Qing Tian

E-bike battery 48V 10Ah Qing Tian