Ni-MH Battery is a good performance battery. Nickel-metal hydride batteries are classified into high-voltage nickel-hydrogen batteries and low-voltage nickel-hydrogen batteries. The positive electrode active material of the nickel-hydrogen battery is Ni(OH)2 (called NiO electrode), the negative electrode active material is metal hydride, also called hydrogen storage alloy (electrode called hydrogen storage electrode), and the electrolyte is 6 mol/L potassium hydroxide solution. Nickel-hydrogen batteries have become more and more important as an important direction for hydrogen energy applications.

Ni-Cd Battery

Ni-Cd Battery is an alkaline storage battery. Its positive plate is nickel hydroxide, the negative plate is cadmium, and the electrolyte is potassium hydroxide or sodium hydroxide solution. Nickel-cadmium batteries contain a large amount of Ni, Cd and Fe, among which Ni is an important raw material for steel, electrical appliances, non-ferrous alloys, electroplating, etc. Cd is a rare metal used in batteries, pigments and alloys, and has a huge poison, which must be scrapped. Recycle. In order to recover cadmium, nickel, iron materials and plastics from nickel-cadmium batteries, the following treatment procedures are generally used:

(1) Mechanical disassembly and discharge of electrolyte: Separate the bracket and shell of the large battery, and the discharged KOH is neutralized with potassium salt and discarded.

(2) pulverization, sieving and physical separation: sieving and magnetic separation according to the particle size and magnetic susceptibility of different materials. Fine-grain electrode materials and coarse-grained stainless steel, iron scrap and plastic are obtained, and the latter two types are separately neutralized with acid, washed with water and separately recovered.

(3) Chemical metallurgical treatment: chemical metallurgical treatment of the active electrode material to obtain metal cadmium, nickel or a compound reagent thereof.

As a Ni-Cd Battery Pack Manufacturer, share the recycling process of the battery.

Waste nickel-cadmium battery recycling technology is generally divided into two major types of fire technology and wet technology.

The fire process is simple, can effectively recover pure Cd, prevent Cd from polluting the environment, and can recover iron group metals. It has obtained more industrial applications in developed countries such as the United States, Sweden, France and Japan. However, the fire smelting method should be carried out under the high temperature condition of 90~1000 °C, the energy consumption is high, and a large amount of high temperature dusty furnace gas needs to be processed, and the metal recovery rate and product purity also need to be improved.

The traditional hydrometallurgical process is currently unable to recover a small amount of Co in the raw materials, and the electrolysis conditions are strict. Therefore, in order to more effectively recover valuable metals from waste Ni and Cd batteries, in addition to continuous improvement of traditional processes, new treatment processes are still being researched at home and abroad. Among them, solvent extraction and ammonia leaching are two promising recycling processes.

Precautions

1. It can be stored within the temperature range of -30 °C - 50 °C, but if it is placed for a long time, please keep it below 35 °C;

2. The state of charge or the state of the discharge state is possible, but the discharge state can make the capacity recover earlier and is easier to activate;

3. When the battery is left for a long time, it must be fully charged before use.

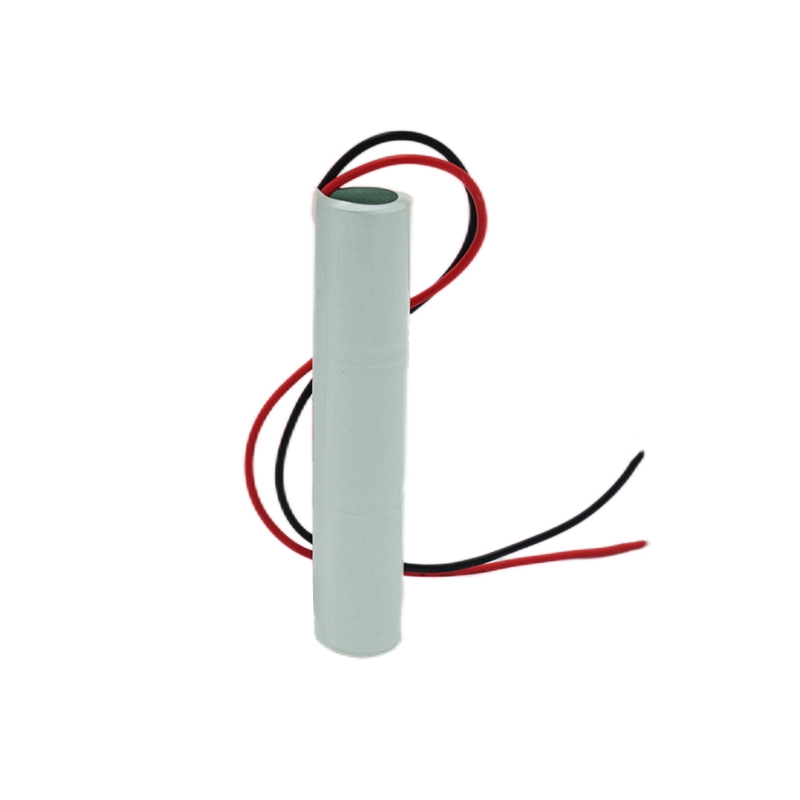

Ni-MH Battery C4700mAh 3.6V

Ni-MH Battery C4700mAh 3.6V Nickel Cadmium Nicd Battery Pack SC1800mAh 3.6V

Nickel Cadmium Nicd Battery Pack SC1800mAh 3.6V Ni-Cd Battery Pack D4000mAh 3.6V

Ni-Cd Battery Pack D4000mAh 3.6V Ni-Cd Battery Pack C2500mAh 3.6V

Ni-Cd Battery Pack C2500mAh 3.6V NICAD Battery Pack AA900mAh 3.6V

NICAD Battery Pack AA900mAh 3.6V LiFePO4 IFR18650 1600mAh 3.2V

LiFePO4 IFR18650 1600mAh 3.2V LiFePO4 IFR18650 1600mAh 6.4V

LiFePO4 IFR18650 1600mAh 6.4V Ni-MH Battery C4000mAh 3.6V

Ni-MH Battery C4000mAh 3.6V E-bike Battery 48V 10Ah JL-1

E-bike Battery 48V 10Ah JL-1 E-bike battery 48V 10Ah Qing Tian

E-bike battery 48V 10Ah Qing Tian